MOTOR

If you're suffering delayed motor response when you open the throttle, go to the Batteries page and follow the instructions there under Connection Problems.

Some editions of the Torq manual give details for greasing the motor gears. These instructions give the impression that the gears are just behind the motor's removable cover. That is not in fact the case, opening the cover will only reveal the armature windings. These instructions only apply to some other models in the eZee range. Access to the Torq and Quando motor gears can only be had by full withdrawal of the complete spindle/armature assembly. For details on how to do that, see this section on servicing.

If a loud rhythmic ticking, knocking or clunking noise is experienced, this can be due to water in the controller, or loss of one of the connections of the five Hall effect control wires. These are the five fine wires leading from the motor to the controller via soldered joins within the heatshrink sleeve alongside the Torq's front fork. On the Quando the wires go direct to the controller area. For advice on these problems, see Wiring and Diagnosis . The purpose of these wires is to inform the controller of the status of the motor's armature windings at any point of rotation and thus enable the motor to have drive smoothly applied from a standstill. Many cheap electric bikes using Hall effect motors dispense with these, and that's why they have to be pedalled initially to about two to three mph to enable the motor to then carry on. However, it's not possible to just cut the Hall effect control wires on the eZee motor, since the controller also has to be changed to a simpler version for the motor to work in the other mode, hence that knocking when a connection is lost.

There are no serviceable electrical components within the front hub. Once the hub motor is found to perform satisfactorily in normal use, it's likely to continue like that indefinitely without any electrical fault.

See the Diagnosis and Wiring pages. Cross referencing links on both pages.

Page updated 16.11.2010

.

Motor Details and Servicing

For the operating principles and operation sequences of a typical Hall sensor motor, click here.

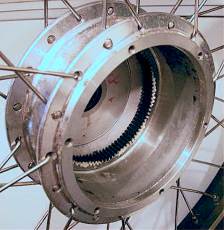

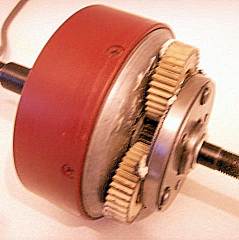

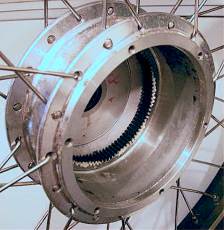

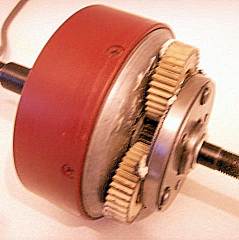

On the left you see the static armature on it's spindle, the multiple poles and their windings evident. On the left side of the thick section of the spindle you see the slot from which the wires emerge to connect to the armature windings and Hall effect sensors which lie buried within. Around the armature is the rotor, a drum which carries a ring of slim bar magnets against which the phase pulses operate and which are read for position by the Hall effect sensors as they pass. The centre photo shows the other side of the rotor with the orbital gears linked to the centre gear wheel and the freewheel beyond. Those orbital gears act on the greased orbital ring gear seen in the back of the hub shell of the third photo. The steel housing for the ball race bearing is seen in the centre of the rear hub wall, and the right hand motor side plate has the same bearing. The gears have high temperature grease applied during manufacture and should be ok for a very long time, but servicing at around 5000 to 10,000 miles is advisable.

Stripping the Motor

To strip the motor after the wheel is removed, remove the six crosshead bolts on the side plate, then take off the nut on the opposite side of the spindle, holding the spindle still by it's flats with a suitable snug fitting spanner. Then with a mallet or hammer give the spindle end opposite the cover end a sharp tap which will break the cover seal, then you'll be able jiggle the cover off with it's internal bearing. Take great care not to damage the wiring where it energes from the spindle centre. Now the whole motor core can be withdrawn from the hubshell. The bearings remain in the hubshell sides but watch out for any displaced shims that belong on the inner spindle end since they correctly register the motor internally and must be replaced when reassembling.

Apply fresh silicone grease to the gears, preferable using a small brush and not smearing it too thickly, excess will just squeeze out and leave a mess inside the motor.

In the event of gear failure, new gear sets are available from the eZee agents linked to on the home page and they come complete with the hub shell rack. The rack is held in place by small bolts so it is easily replaceable. In the case of any difficulties, advice is always available online from members of the friendly Pedelecs forum linked to on the home page, with many past and present Torq and Quando owners amongst them.